cmm BRIDGE | ares

CMM bridge | ares

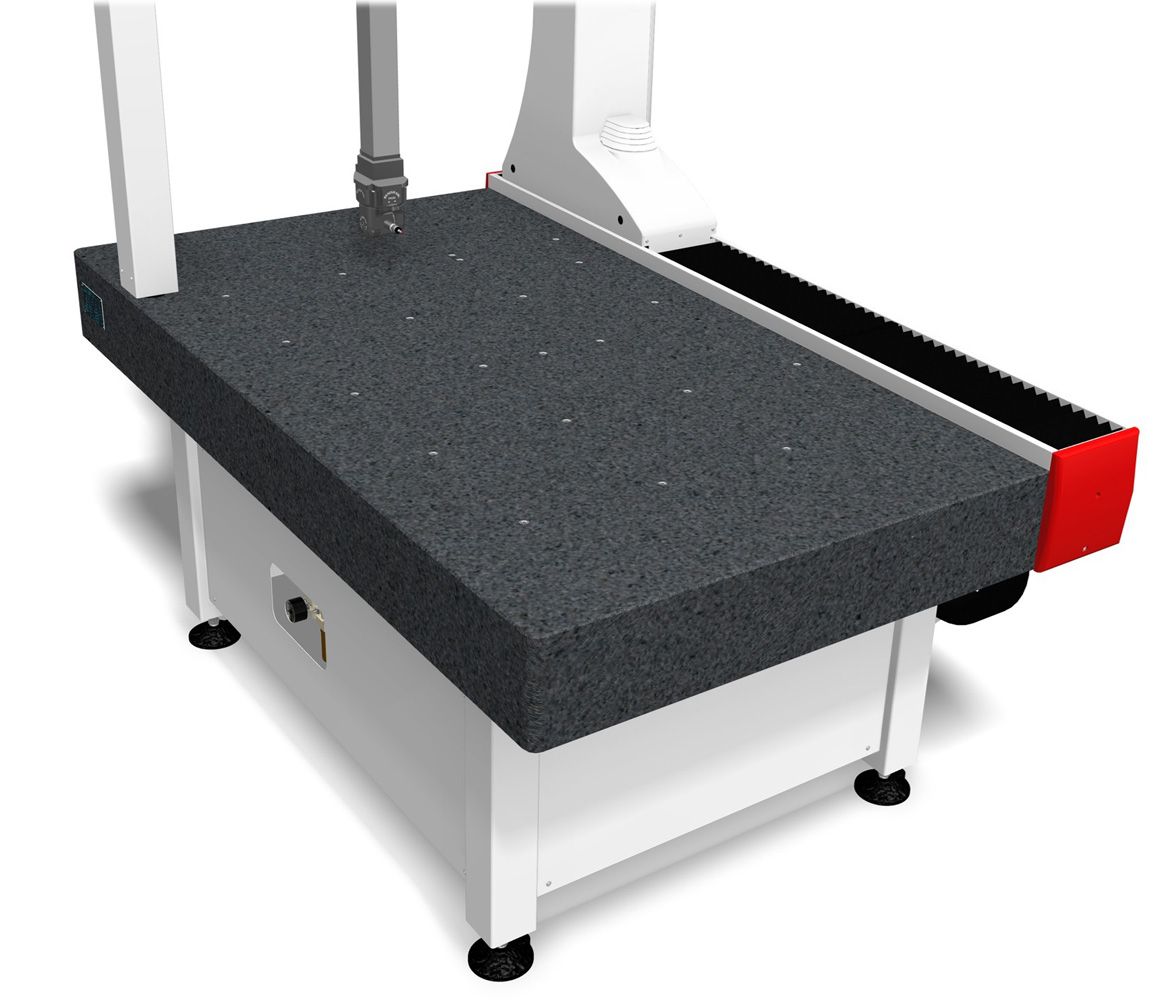

ARES CMMs have a lower overall height compared to most CMM solutions available on the market. They may also be provided with a low profile support stand to reduce the overall height by an additional 100 mm.

This particular features makes ARES especially suitable for inspection laboratories with low ceilings.

ARES CMMs are available in manual or CNC configuration; manual units may be optionally upgraded to a full CNC version at a later date.

Two performance levels are available:

- ARES: for standard applications.

- ARES NT: per for higher performance requirements. The ARES NT model has a silicon carbide Z-axis column that increases the overall stiffness of the measuring platform.

CMM ares

CMMs are available with bridge widths of 500 mm and 700 mm, and are perfectly suitable for workshops.

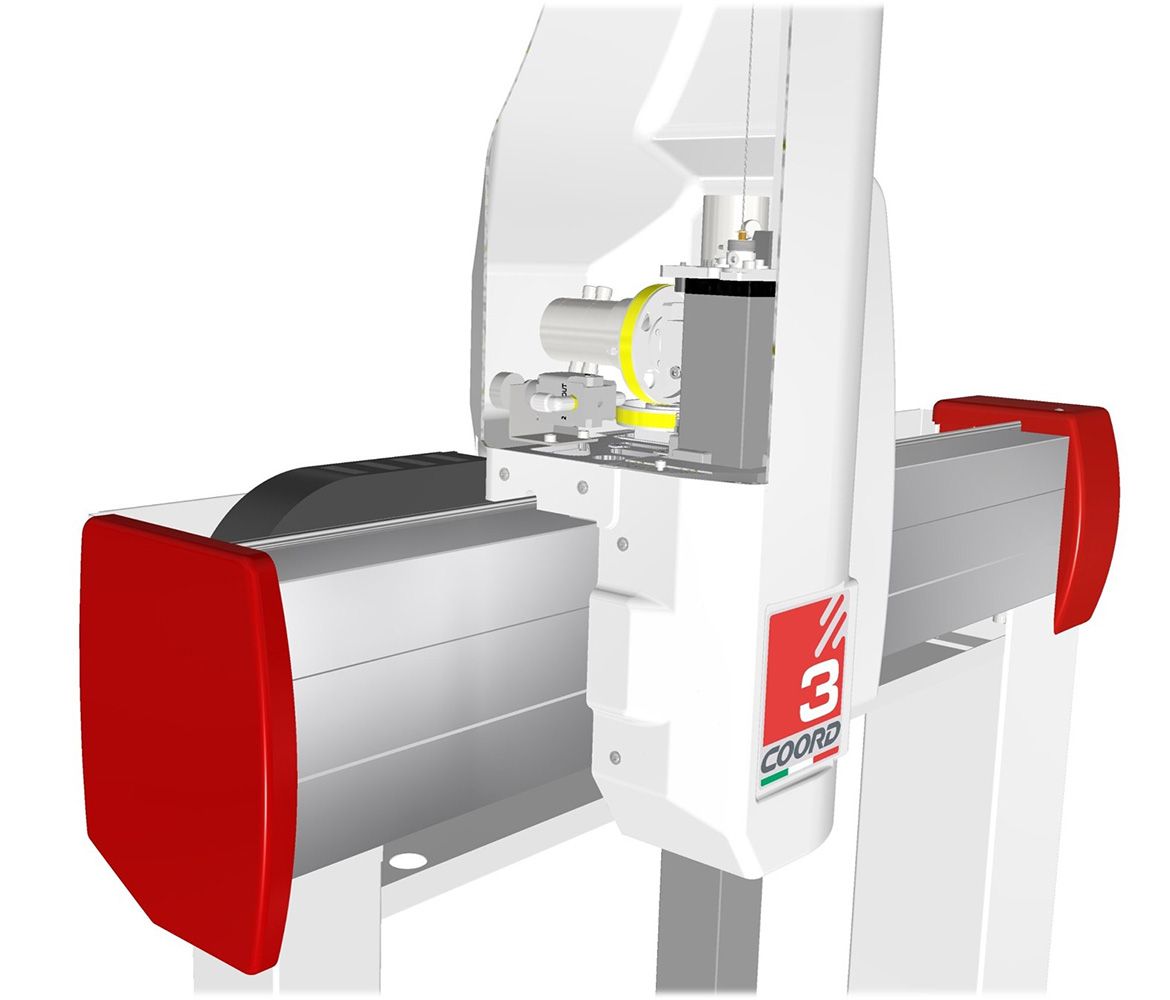

- Ultra-rigid alloy CMM frame provides maximum stiffness for scanning applications

- Rapid thermal diffusion structure when environment conditions change

- FEA-designed bridge beam extrusion to optimize the moment of inertia and ensure minimum deflection when operating at high accelerations

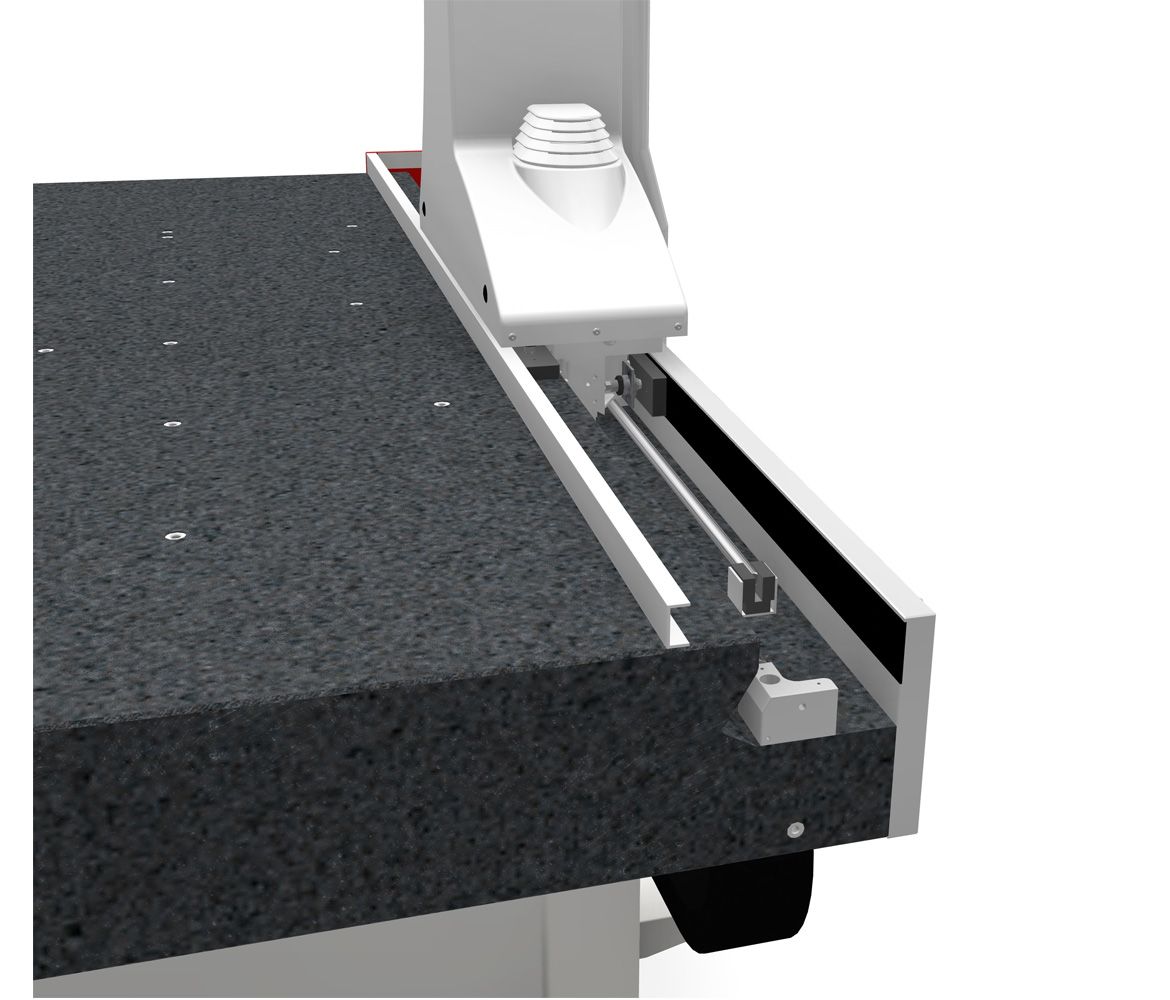

- M8 threaded table fitted in a wide grid pattern

- Rigid air bearings for wide bearing spread ratios

- Pneumatic Z-axis counterbalance

- Free-floating, 0.1-micron resolution measuring scales with incorporated dynamic signal processing

- Fully digital motion control with probe path blending for optimized performance

- Zero hysteresis friction drives on all axes

- Passive vibration damping system to isolate external vibrations

- Free access to the CMM measuring area from all sides

- Maximum positioning speed: 517 mm/sec

- Maximum acceleration: 1730 mm/sec2

- Silicon carbide Z-axis column for greater rigidity

- Optional Renishaw TONiC 0.1-micron resolution measuring scales

- Dynamic wireless thermal compensation system including part temperature sensor.

- Nominal temperature: 20 °C

- Metrological temperature range: metrologica: 18 – 22 °C

- Temperature gradient: 0,5 °C/hour – 2 °C/day

- Operating temperature range: 15 – 35°C

- Relative humidity: 40 – 80% (non-condensing)

- Acceptable vibrations: 30 mm/sec2 1-10 Hz | 15mm/sec2 10-20 Hz | 50 mm/ sec2 20-100 Hz

- Minimum air supply: 5 bar

- Air consumption: 100 Nl/min

- Power supply voltage: 230 V 50 Hz o 110 V 60 Hz (+/- 2% single-phase)

- Maximum power consumption: 10 A 1200 W (1600 W the largest models)

All Coord3 CMM products are factory-tested for accuracy according to the UNI EN ISO 10360 – 2 standard

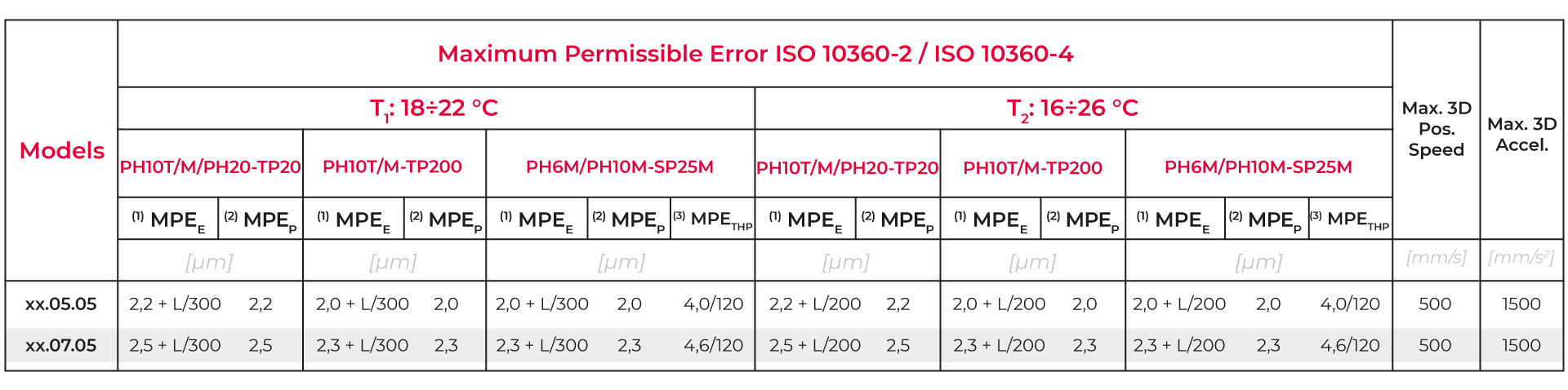

ARES 05.05 / 07.05

Performance data are only valid if the following specifications are met:

– PH10T/M/PH20-TP20/TP-200: Tip diameter Ø 4mm x Stylus length 10mm

– PH6M/PH10M-SP25M: SM1, stylus Ø 5mm x 50mm

– L= measuring length in mm

– CMM equipped with Multisensor temperature compensation system (Optional)

– Ambient temperature Range:

T1 : 18÷22 °C; Max. Gradients: 0,5 °C/h – 2,0 °C/24h – 0,5°C/m

T2: 16÷26°C; Max. Gradients:1,0 °C/h – 5,0 °C/24h – 1,0 °C/m

[1] Maximum Permissible Error of indication for size measurement accordind ISO 10360-2

[2] Maximum Permissible Probing Error according ISO 10360-2

[3] Maximum Permissible Scanning Probing Error according ISO 10360-4, applicable to the SP25M probes only

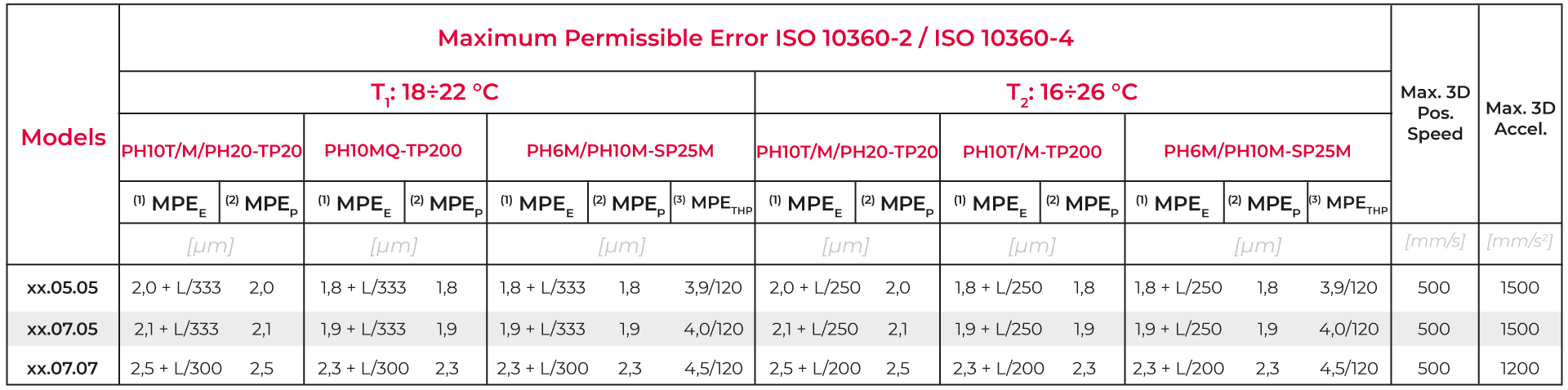

ARES NT 05.05 / 07.05 / 07.07

Performance data are only valid if the following specifications are met:

– PH10T/M/PH20-TP20/TP200: Tip diameter Ø 4 mm x Stylus length 10 mm

– PH6M/PH10M-SP25: SM1, Stylus Ø 5 mm x 50 mm

– L = measuring length in mm

– CMM equipped with Multisensor temperature compensation system (Optional)

– Ambient temperature Range:

T1: 18 ÷ 22 °C; Max. Gradients: 0,5 °C/h – 2,0 °C/24h – 0,5 °C/m

T2: 16 ÷ 26°C; Max. Gradients: 1,0 °C/h – 5,0 °C/24h – 1,0 °C/m

[1] Maximum Permissible Error of indication for size measurement accordind ISO 10360-2

[2] Maximum Permissible Probing Error according ISO 10360-2

[3] Maximum Permissible Scanning Probing Error according ISO 10360-4, applicable to the SP25M probes only

- Laser scanning sensor

- Dynamic wireless thermal compensation of the machine and its components

- Pneumatic vibration isolation system

- Modular part fixing kits

- Models and sizes

COORD3 ARES CMMs are available with the following measuring strokes (X.Y.Z mm):

7.5.5

7.7.5 / 10.7.5 / 12.7.5

7.7.7 / 10.7.7 / 12.7.7

request a visit from one of our agents

Strada Statale 25, n°3 – 10050 – Bruzolo (To) – Italy

PHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

COMMERCIAL SUPPORT

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING OFFICE

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 – 00187 Roma (RM) - Italy | REA C.C.I.A.A. N. 1667509 Roma - Capitale sociale versato: Euro 50.000,00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy