cmm BRIDGE | kronos

CMM bridge | kronos

The sturdy structure and complete structure protection system through guards and gussets enable the KRONOS series to operate in various types of production environments, from the Metrology Room to manufacturing environments.

This CMM is equipped with aportable leverunit for manual control of motorized movement (Arkey).

CMM kronos

The KRONOS series is also available in NT version, equipped with the innovative Silicon Carbide spindle for even higher metrological performance.

- Aluminum alloy moving carriage structure with integrated granite top

- Generously sized Z spindle made of light aluminum alloy or Silicon Carbide (NT)

- Mixed rack-and-pinion and hysteresis-free clutch drive system for smooth and repeatable movement

- Measurement system with high-resolution linear transducers (0.1 µm)

- Multi-sensor automatic temperature compensation system, with part temperature probe

- Temperature range for metrological specifications:

- T1:

Ambient temperature: 18 ÷ 22 °C

Maximum hourly gradient: 1.0 °C/h

Maximum daily gradient: 2.0 °C/24h

Maximum gradient in volume: 0.5 °C/m

- T2:

Room temperature: 16 ÷ 26 °C

Maximum hourly gradient: 1.0 °C/h

Maximum daily gradient: 5.0 °C/24h

Maximum gradient in volume: 1.0 °C/m - Operating Temperature: 15 to 35 °C

- Relative humidity for operation: 40 to 80 % (non-condensing)

- Allowable vibration: (Peak/peak acceleration)

30 mm/s2between 1 and 10 Hz

15 mm/s2between 10 and 20 Hz

50 mm/s2between 20 and 100 Hz

- Pressure: 6 Bar -79PSI

- Air consumption: 160Nl/min

- Power supply: 230 V ± 10%; 50 Hz ± 2% single phase

- Absorption: 10A 1600W

- Manual Heads: MIH, MH20, MH20i

- Indexable Motorized Heads: PH10T, PH10M, PH10MQ

- Point-to-point touchers: TP2, TP20, TP200

- Analog keyers: SP25 scanning analog keyer

- Laser sensors: Metris LC/XC series (including qualification sphere)

- Probe and tip changing systems: Automatic changing stations

Each COORD3 CMM is tested according to UNI EN ISO 10360-2 standards.

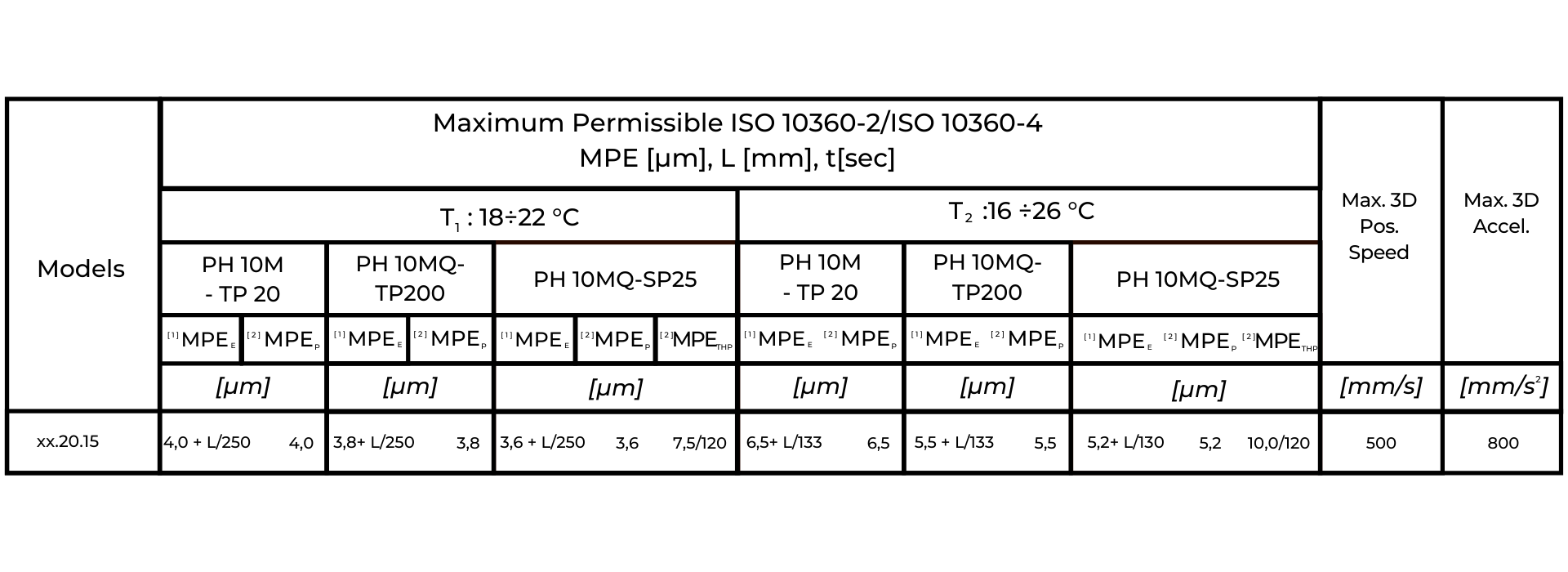

KRONOS NT 20.15

The indicated performance is valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm stylus length 10mm

- PH10MQ/SP25: SM1, stylus Ø 5mm x 50mm

- L= measurement length in mm

- Ambient temperature conditions:

T1 : 18÷22°C; Max gradients: 1.0 °C/h - 2.0 °C/24h - 0.5 °C/m

T2: 16÷26°C; Gradients max: 1.0 °C/h - 5.0 °C/24h - 1.0 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on Point Grip according to ISO 10360-2

[3] Maximum Permissible Error of Point Grip on scanning according to ISO 10360-4 for SP25M/SP80 probes.

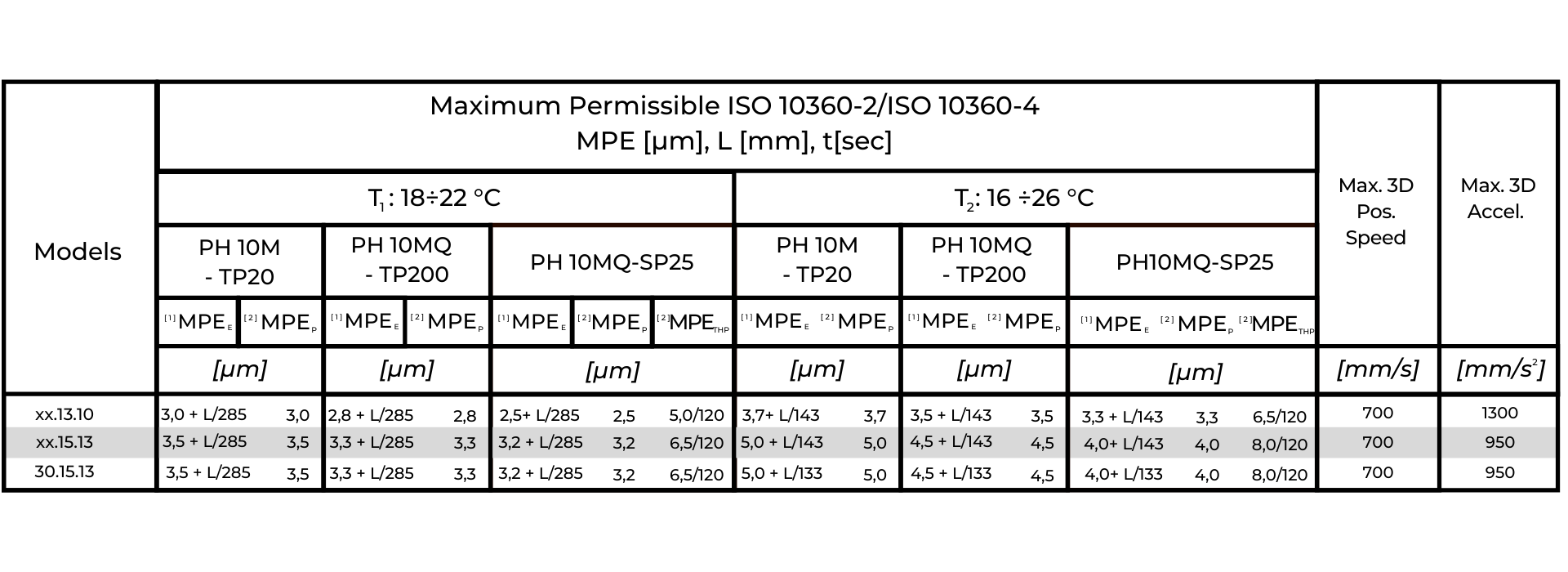

KRONOS NT 13.10 - 15.13

The indicated performance is valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm stylus length 10mm

- PH10MQ/SP25: SM1, stylus Ø 5mm x 50mm

- L= measurement length in mm

- Ambient temperature conditions:

T1 : 18÷22°C; Max gradients: 1.0 °C/h - 2.0 °C/24h - 0.5 °C/m

T2: 16÷26°C; Gradients max: 1.0 °C/h - 5.0 °C/24h - 1.0 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on Point Grip according to ISO 10360-2

[3] Maximum Permissible Error of Point Grip on scanning according to ISO 10360-4 for SP25M/SP80 probes.

- Passive Antivibration System

- Active vibration damping system (AVM)

- Multi-wire wiring

- Manual/automatic pallet loading/unloading system

- PC and Printer

- Training at Coord3 center or agents

- Installation by Coord3 staff or agents

- Models and dimensions:

COORD3 KRONOS CMMs are available with the following measuring strokes (Y.Z mm):

13.10/15.13/20.15

request a visit from one of our agents

Strada Statale 25, No. 3 - 10050 - Bruzolo (TO) - Italy

TELEPHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

SALES

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 - 00187 Roma (RM) - Italy | REA C.C.I.A.A. No. 1667509 Rome - Paid-up share capital: Euro 50,000.00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy