cmm gantry | mct starlight

CMM gantry | mct starlight

MCT SL is a range of medium-to-large Gantry CMMs that stand out for their excellent structural stability and flexibility.

MCT STARLIGHT is also available in the NT LIGHT configuration, which features a Z ram in light aluminium alloy and a “Single Read” system on the X-axis.

mct starlight

- Generous distance between bearings for optimum mechanical rigidity

- Main Y carriage with high rigidity and exclusive tubular steel structure

- Z ram in extruded aluminium alloy to guarantee rigidity and minimize inertia

- X beams with large transversal section in stabilised steel, equipped with a support system to allow for linear expansion without risking distortion

- Ground X/Y axes guide-ways in high-resistance epoxy resin (roughness 0.4 mm)

- Measuring system with high-resolution linear transducers (0.1 μm) with “Dual Reader” system on the longitudinal Xaxis

- “Dual Drive” system on main X carriage (optional, standard for stroke Y=3000)

- Automatic, multi-sensor system for compensating errors due to the thermal elongation of structural elements

Temperature range for metrological specification:

- Ambient temperature: 18 ÷ 22 °C

- Maximum hourly gradient: 1.0 °K/h

- Maximum daily gradient: 2.0 °K/24h

- Maximum volume gradient: 0.5 °K/m (SL NT) – 1.0 °K (SL)

- Operating temperature: 15 ÷ 35 °C

- Operating relative humidity: 40 ÷ 80% (non-condensing)

- Allowed vibrations:

(acceleration between peaks)

30 mm/sec 2 from 1 to 10 Hz

15 mm/sec 2 from 10 to 20 Hz

50 mm/sec 2 from 20 to 100 Hz

- Minimum air supply: 6 bar

- Air consumption: max. 300 Nl/min

- Power supply voltage: 230 V ± 10% | 50 Hz ± 2% (singlephase) 115 V ± 10% | 60 Hz ± 2% (single-phase)

- Manual probe heads: MIH, MH20, MH20i

- Motorised probe heads: PH10M, PH10MQ

- Motorised indexable probe heads: PH20, REVO

- Point to point trigger probes: TP2, TP20, TP200

- Analogue contact probes: SP600, SP25M, SP80

- Stylus and probe changers: Fully automatic changing stations

All Coord3 CMM products are factory-tested for accuracy according to the UNI EN ISO 10360 – 2 standard

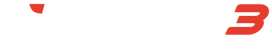

The services indicated are valid under the following conditions:

– TP2/TP20-5W/TP200: Ø4mm x stylus length 10mm

– SP25: SM1, stylus length 50mm Ø5mm

– REVO: RSP2/RSH175 – RSP3-1/SH25-1, stylus length 20mm

– SP80: Ø 5mm stylus length 50mm

– L= measuring length in mm

– Ambient temperature conditions:

T : 18÷22 °C; Degrees max: 1,0 °C/h – 2,0 °C/24h – 1,0 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum permissible point gripping error according to ISO 10360-2

[3] Maximum permissible error of scanning point gripping according to ISO 10360-4 standard for SP25M / SP80 / REVO probes

MCT STARLIGHT NT

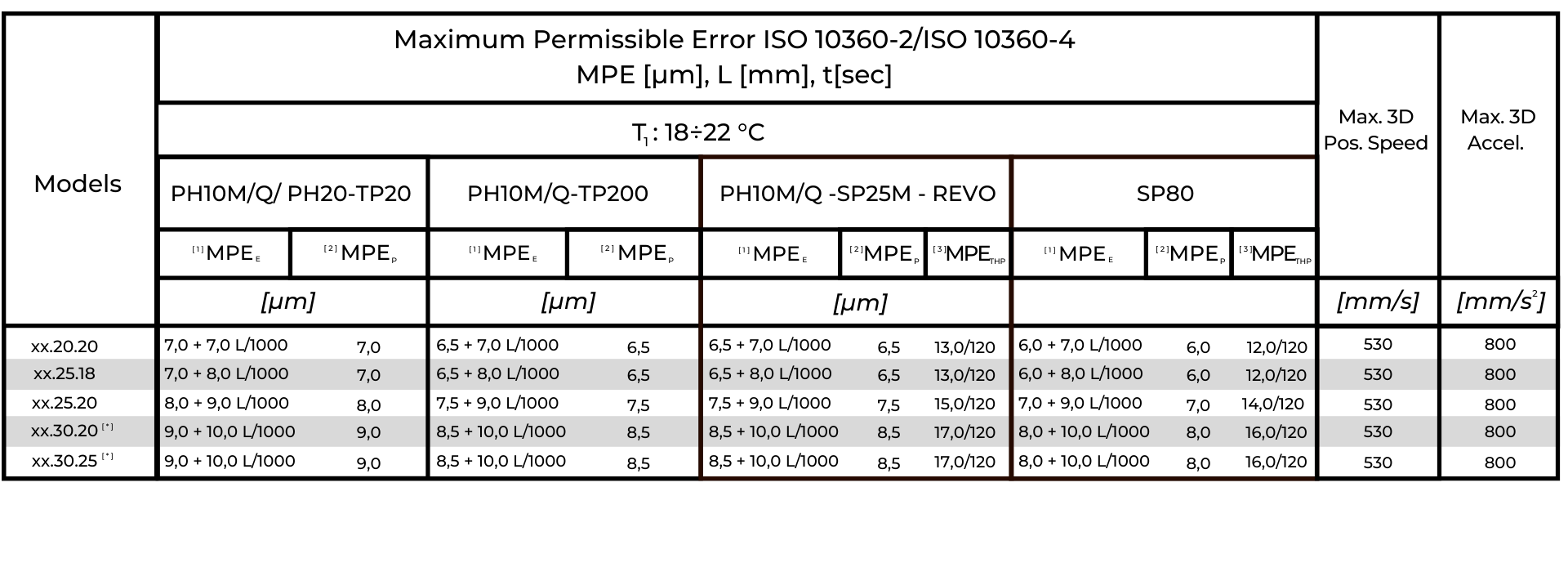

The services indicated are valid under the following conditions:

– TP2/TP20-5W/TP200: Ø4mm x stylus length 10mm

– SP25: SM1, stylus length 50mm Ø5mm

– REVO: RSP2/RSH175 – RSP3-1/SH25-1, stylus length 20mm

– SP80: SM1, Ø 5mm stylus length 50mm

– L= measuring length in mm

– Ambient temperature conditions:

T : 18÷22 °C; Degrees max: 1,0 °C/h – 2,0 °C/24h – 0,5 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum permissible point gripping error according to ISO 10360-2

[3] Maximum permissible error of scanning point gripping according to ISO 10360-4 standard for SP25M / SP80 / REVO probes

- Multi-wire cables

- Models and sizes:

COORD3 MCT STARLIGHT CMMs are available with the following measuring strokes (Y.Z mm):

20.20/25.18/25.20/30.20/30.25

request a visit from one of our agents

Strada Statale 25, n°3 – 10050 – Bruzolo (To) – Italy

PHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

COMMERCIAL SUPPORT

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING OFFICE

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 – 00187 Roma (RM) - Italy | REA C.C.I.A.A. N. 1667509 Roma - Capitale sociale versato: Euro 50.000,00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy