cmm BRIDGE |

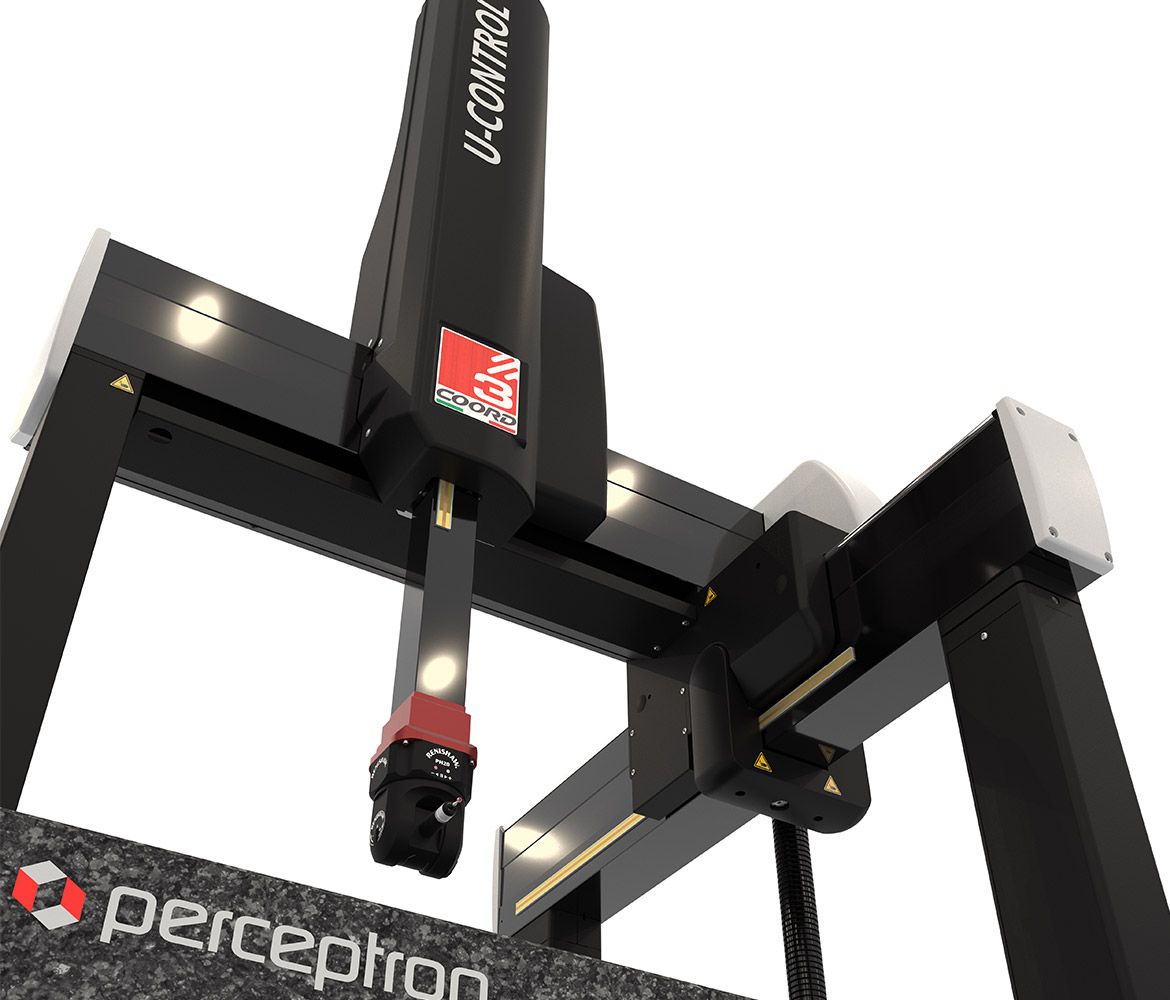

u-control

CMM bridge | u-control

The open structure of the U-CONTROL solution offers an outstanding ergonomic design. Thanks to its compact size, it is perfect for quality control rooms or production environments.

The fully equipped U-CONTROL solution with air bearings ensures an accuracy of 2.5 microns. The standard version is equipped with a Renishaw touch-probe and can be supplied with a motorized probe head for fully automated inspection applications.

The U-CONTROL CMM is particularly suitable for small workshops.

CMM u-control

- Ultra-rigid platform in advanced alloy

- Rapid thermal diffusion through advanced alloy CMM frame when temperatures change

- FEA design provides optimum moment of inertia and stiffness, allowing high accelerations

- One-piece granite base plate with M8 threaded table inserts with wide grid pattern

- Rigid air bearings

- Pneumatic Z-axis counterbalance

- 0.1-micron resolution measuring scales with dynamic signal processing

- Quick and easy installation with pre-assembled monobloc shipping

- Overall dimensions optimized due to an integrated control

- Zero hysteresis friction drives to all axes

- Passive vibration damping system to isolate external vibrations

- Free access to the CMM measuring area

- Maximum positioning speed: 500 mm/sec

- Maximum acceleration: 1500 mm/sec2

- Nominal temperature: 20 °C

- Metrological temperature range: 18 – 22 °C (Extended range: 16 – 26 °C)

- Temperature gradient: 0.5 °C/hour – 2 °C/day (Extended range: 5 °C/day)

- Operating temperature range: 15 -35 °C

- Relative humidity: 40 – 80% (non-condensing)

- Acceptable vibrations: 30 mm/sec2 1-10 Hz | 15mm/sec2 10-20 Hz | 50 mm/sec2 20-100 Hz

- Minimum air supply: 5 bar (72 PSI)

- Air consumption: 90 NL/min (3 cfm)

- Power supply voltage: 230 V 50 Hz or 110 V 60 Hz

- Maximum power consumption: 10 A, 1200 W

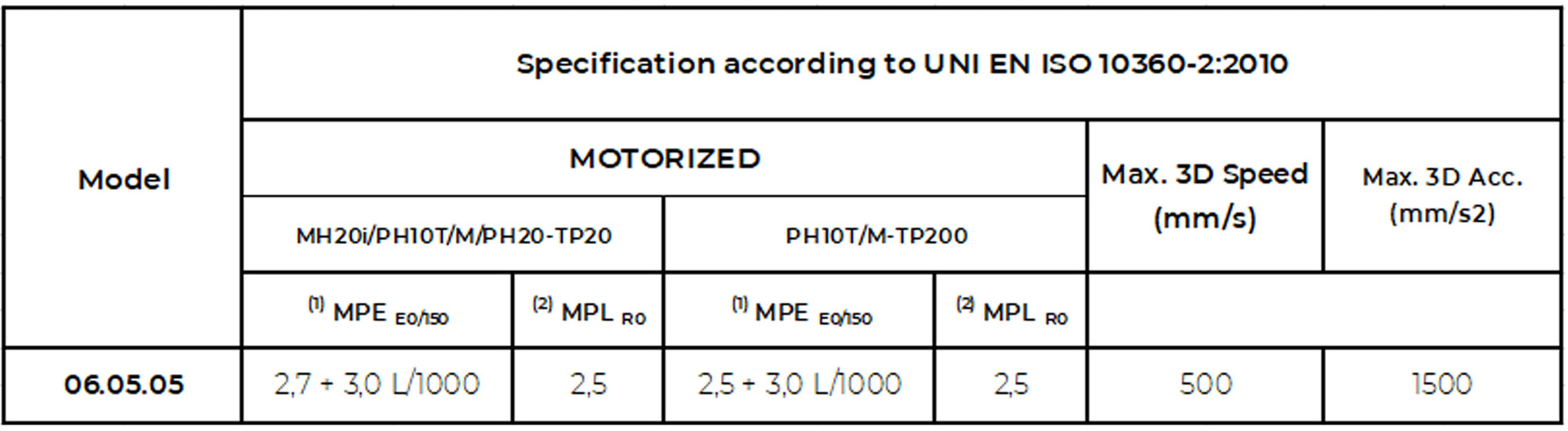

All COORD3 CMM products are factory-tested for accuracy according to the UNI EN ISO 10360 – 2 standard.

Performance data are only valid if the following specifications are met:

- PH10T/M/PH20-TP20/TP200: Tip diameter Ø 4 mm x Stylus length 10 mm

- MH20i-TP20: Tip diameter Ø 4 mm x Stylus length 10 mm

- L = measuring length in mm

- Ambient temperature Range: T: 18 ÷ 22 °C;

Max. Gradients: 0,5 °K/h – 2,0 °K/24h – 0,5 °K/m

(1) Maximum Permissible Error according UNI EN ISO 10360-2:2010

(2) Maximum Permissible Limit according UNI EN ISO 10360-2:2010

- Optional CMM touch station for enhanced ergonomics

- Dynamic thermal compensation of machine and part

- Pneumatic vibration isolation system

- Air dryer

- Modular part fixture kits

request a visit from one of our agents

Strada Statale 25, n°3 – 10050 – Bruzolo (To) – Italy

PHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

COMMERCIAL SUPPORT

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING OFFICE

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 – 00187 Roma (RM) - Italy | REA C.C.I.A.A. N. 1667509 Roma - Capitale sociale versato: Euro 50.000,00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy